Fillet Weld Legs Determine Size and Throat of Fillet Welds Fillet weld sizes determine theoretical throat. The product of the size and cos45°in case where an isosceles right triangle may inscribe within the fillet weld cross section:S×cos45°= 0.7S, as shown in Fig. 2 - How to calculate theoretical throat. The throat thickness bisects the isosceles triangle, splitting the single triangle into two right triangles with the throat thickness on one side and the leg of the fillet weld being the hypotenuse. Thus the leg of the fillet weld is found to be L = T/COS(45) or as commonly approximated L= T/(0.7). Given: Weld throat thickness = 8.2 mm. Formula: Weld size (h) = t √2 - ( It is the relation between weld size and weld throat thickness) Solution: weld size (h) = t √2. Weld size (h) = 11.59 mm. The effective area of a weld is calculated by multiplying the length of the weld times the throat of the weld. For design purposes we use the theoretical throat as shown below. In the above diagram, is the fillet weld leg size. The theoretical throat is calculated. Video 5 Dimension of the complete fillet weld 1) size of the fillet weld 2) length of the fillet weld 3) pitch of the fillet weld 4) chain intermittent fille.

Unless you are a design engineer you typically don’t have to worry about determining the strength of a weld. The strength of a weld refers to its load carrying capacity, or how much load it can handle before it fails. However, it is very important for all of us involved in the welding process, from welders to production supervisors to quality personnel and welding engineers to understand the basics of weld design.

Overwelding is an epidemic in our industry. This stems from not really understanding how to properly size a weld. But even companies with teams of engineers, having the luxury of using finite element analysis software, still call for weld sizes much bigger than necessary. This overwelding can have a tremendous impact on cost. To get an idea of how much you can read: Cost of Overwelding.

Having a basic understanding of how to properly size welds will equip you to question the size of certain welds. We are not telling you to go out and reduce all weld sizes immediately. Any change of this magnitude must be reviewed and approved by engineering. However, the savings can be significant.

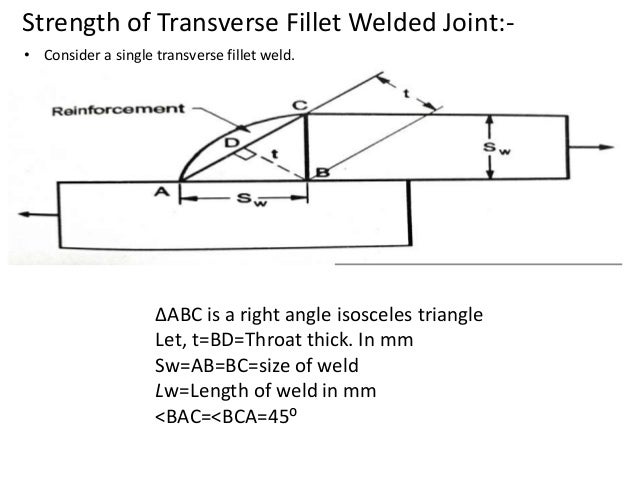

To explain how to determine the strength of a weld we will use a simple example. In this article we will discuss only how to determine the strength of a transverse fillet weld. A transverse fillet weld is one that is perpendicular to the force applied as seen in the image below.

Because the load is perpendicular to the weld it is considered a tensile load. The formula we need to use to determine the load carrying capacity of the weld is:

Where

Fillet Weld Effective Throat

σt is the tensile strength of the weld (determined by the filler metal being used) in PSI

F is the force the weld can handle, in other words, the strength of the weld in lbf

A is the effective area of the weld

The effective area of a weld is calculated by multiplying the length of the weld times the throat of the weld. For design purposes we use the theoretical throat as shown below.

In the above diagram, is the fillet weld leg size. The theoretical throat is calculated by multiplying times the cosine of 45˚ which is 0.707. For all fillet welds with both legs being of the same size, the theoretical throat will be 0.707 x .

If the weld is 20 inches in length then the effective area will be 20 x 0.707 x .

Keeping with our example, there are two welds joining the two members. Both welds have a leg size of ¼-in and are 20 inches in length. We want to determine the maximum load these welds can withstand. The welding is being done with an ER70S-6 GMAW wire with minimum tensile strength of 70,000 psi.

First, determine the throat size.

Throat = x cos 45˚ = (1/4) x (0.707) = 0.177”

Now determine the effective area of the weld. Remember, there are two 20-inch long welds.

Effective Area = 2 x length x throat = (2) x (20) x (0.177) = 7.08 sq-in

Now we go back to our main formula.

Because we are using an ER70S-6 wire, is equal to 70,000 psi. Now we have all the values except for the one we are solving for, F.

We rearrange the formula to solve for F.

F = (70,000) x (7.08) = 495,600 lbf

So our 20-inch long, double-sided, ¼” fillet welds have a load carrying capacity able to withstand a tensile force of almost half a million pounds. To put this in perspective, a Boeing 747-400 weighs roughly 404,600 pounds. So, our seemingly tiny welds can pick up a 747! That is pretty impressive. However, before you go to the airport and put this to the test there are a few things you should know.

- If the force is applied rapidly the weld would fail at a significantly lower load

- If the force is not applied perfectly evenly along both welds the welds would fail at a significantly lower load

- If there are any weld discontinuities such as cracks, craters on undercut, the welds would fail at a significantly lower load

- If the load is not perfectly static, the welds would fail at a significantly lower load

- If the load is not perfectly perpendicular to the welds, the welds would fail at a significantly lower load

The list of “ifs” keeps going. Because of this, welding codes introduce a factor of safety. Factors of safety are used to make sure we don’t overload structures. In our next post we’ll provide an example of fillet welds loaded in shear. This is basically the worst case scenario and limits the maximum force that can be applied to a weld before it fails. Most of the design is made with the assumption that fillet welds will be loaded in shear.

A word of caution: the above calculations are used to explain the theory behind weld design. It is a simplified example to illustrate certain design principles. Proper testing and approvals by engineering must be in place before any changes can be made to welds when a specific size has previously been determined.

Reference: Design of Welded Structures

Formulae_IndexNomenclatureWeld Strength Calculations

Introduction..... Relevant Standards..... Variables Associated With Welds.....

Guidance Principles..... Table Basic Weld Calcs...... Assessment of Fillet Welds.....

Examples of Fillet Welds Calcs..... Properties of Fillet Welds as lines.....

Example of torsion weld calc. using vectors..... Capacities of Fillet Welds..... Design Strength of Fillet Welds.....

| Introduction The following notes are general guidance notes showing methods ofcalculation of the strength and size of welds. Welded joints are oftencrucially important affecting the safety of the design systems. It isimportant that the notes and data below are only used for preliminary designevaluations. Final detail design should be completed in a formal wayusing appropriate codes and standards and quality reference documents Relevant Standards BS 5950-1:2000 ..Structural use of steelwork in building. Code of practice for design. Rolled and welded sections BS EN 10025-1:2004 - Hot rolled products of structural steels. General technical delivery conditions Variables related to welded joints

Guidance Principles A generous factor of safety should be used (3-5) and if fluctuatingloads are present then additional design margins should be included to allow for fatigue The table below provides provides approximate stresses in, hopefully, a convenientway. Table of bracket weld subject to direct and bending stresses

Assessment of Fillet Weld Groups ref notes and table Properties of Fillet Welds as lines Important note: The methods described below is based on the simple method of calculationof weld stress as identified in BS 5950- clause 6.7.8.2 . The other method identifed in BS 5950 - 1 clause 6.7.8.3as the direction method uses the method of resolving the forces transmittedby unit thickness welds per unit length into traverse forces (FT ) andlongitudinal forces (FL ). I have, to some extent,illustrated this method in my examples below Examples of Fillet Weld Calculations

Properties of weld groups with welds treated as lines - It is accepted that it is reasonably accurate to use properties based onunit weld thickness in calculation to determine the strength of welds as shown in the examples onthis page. The weld properties Ixx Iyy and J are assumedto be proportional to the weld thickness. The typical accuracy of this method ofcalculation is shown below... This is illustrated in the tabled values below

Note: The error identified with this method is lower as h increasesrelative to d. This error is such that the resulting designs are conservative. Example illustrating use of stress vectors

Note: The example above simply illustrates the vector method adding direct and torsional shear stresses and compares the differencein using the unit weld width method and using real weld sizes. The example calculates the stress levels in an existing weld groupit is clear that the weld is oversized for the loading scenario. The difference in the resulting values are in less than 4%. If the welds were smalleri.e 3mm then the differences would be even smaller. Table properties of a range of fillet weld groups with welds treated as lines -

Table Of Weld Capacities The fillet weld capacity tables related to the type of loading on the weld. Twotypes of loading are identified traverse loading and longitudinal loading as show below The weld loading should be such that { (FL/PL) 2 + (FT/PT) 2 } ≤ 1 The following table is in accord with data in BS 5950 part 1. Based ondesign strengths as shown in table below ... Design Strength PL = a.pw PT based on elements transmitting forces at 90o i.e θ = 45o and K = 1,25

Design Strength p w of fillet welds

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Useful Related Links

|